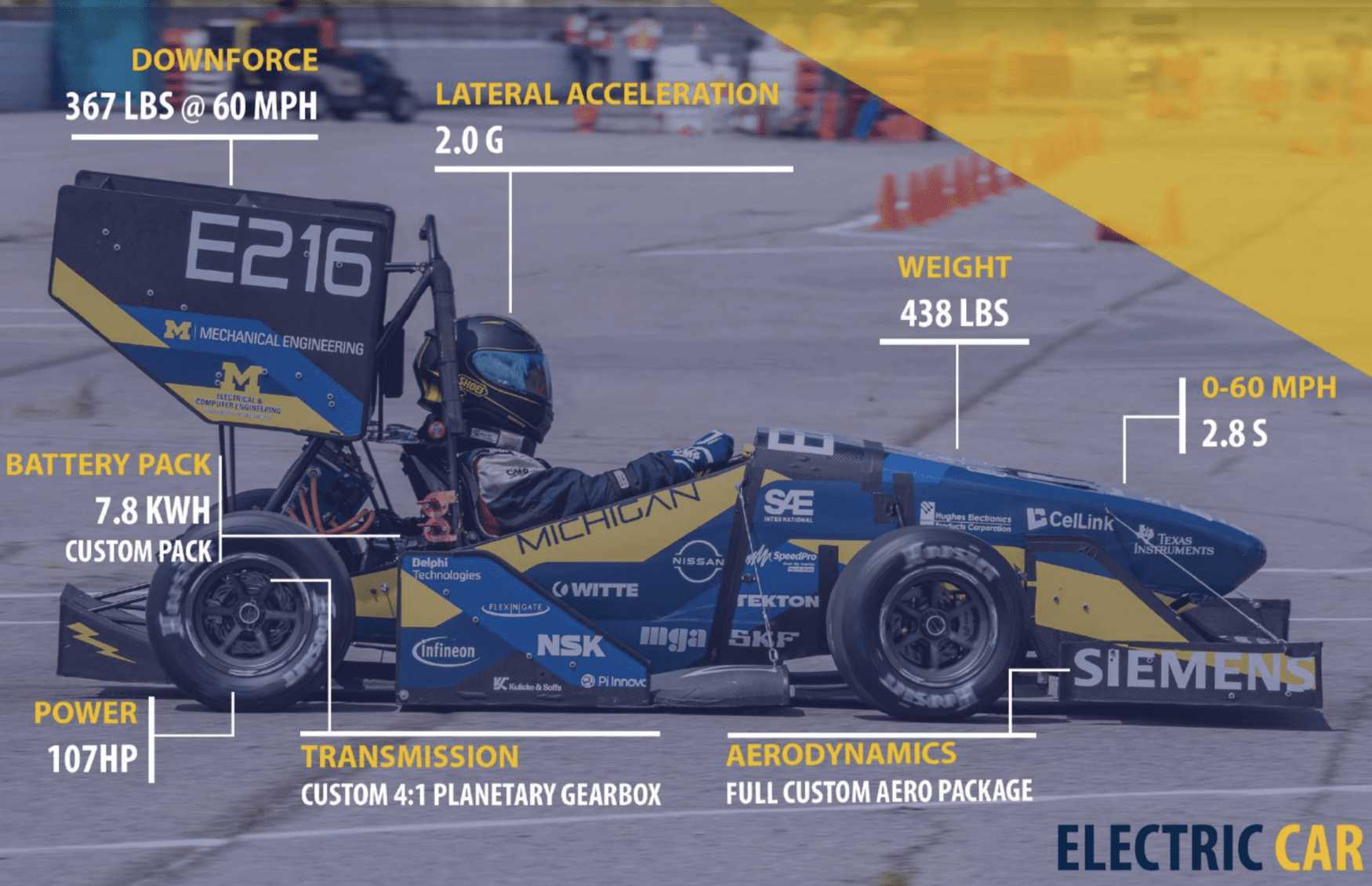

MRacing — the University of Michigan’s Formula SAE team — is tasked each year with designing a formula-style race car to race against other college teams worldwide. This year, the design engineering team wanted to make sure their 36th vehicle was built for strength and speed to compete against fully electric race car competitions in both North America and Europe.

View this post on Instagram

Ranked 5th in the world out of 600 teams, the MRacing team had a reputation to uphold. They reached out to CThru Metals, hoping to leverage our expanded metal foil’s high strength-to-weight ratio to complete the vehicle’s design specifications, and our team was happy to help.

The MRacing vehicle contains carbon fiber throughout its battery pack housing and monocoque chassis. By inserting expanded metal foil under the top ply of the car’s composite layups, the foil acted as a grounding layer across the surface of the carbon fiber parts. Because the car can become conductive, this expanded metal foil solution delivered the dual benefit of shielding the car’s high-voltage electronics in accordance with FSAE regulations, while also allowing the car to maintain top speed and performance.

More on Expanded Metal Foil’s Benefits

Expanded metal foil outperforms woven wire and perforated metals in conductivity, strength, stability and waste generation. More industries and applications are turning to expanded foil for these reasons — CThru’s foil is used in lightning strike protection for aircraft, wind turbine blades, and other carbon fiber uses for batteries, and fuel cells.

From one engineering team to another, we hope our donation of expanded metal foil helps bring the MRacing team another winning season in their upcoming competitions! If you have any questions about how expanded metal foil can assist in your project, please don’t hesitate to contact our team today.

Tags: expanded metal foil

Comments are closed