At CThru MeshTM, we specialize in high-quality metal solutions to meet the needs of various industries and applications. As part of our capabilities, we offer expanded metal foil made from materials such as copper, steel, nickel, titanium, and aluminum. This lightweight metal coil has been precisely slit and stretched to create a mesh material with a uniform pattern of openings.

At CThru MeshTM, we specialize in high-quality metal solutions to meet the needs of various industries and applications. As part of our capabilities, we offer expanded metal foil made from materials such as copper, steel, nickel, titanium, and aluminum. This lightweight metal coil has been precisely slit and stretched to create a mesh material with a uniform pattern of openings.

Expanded metal foil outperforms woven wire and perforated metals in conductivity, strength, stability and waste generation. It is formed using a single, continuous metal sheet to provide high-level strength and support while still allowing air, water and light to pass through.

Manufacturing Capabilities

Materials

The manufacturing of expanded metal mesh is compatible with a broad range of polymers and metals, each with unique properties suitable for varying environments and applications. Products produced from sheet metal include:

- Copper expanded mesh

- Titanium expanded mesh

- Aluminum expanded mesh

- Steel and stainless-steel expanded mesh

Some of the other materials we use to manufacture expanded metal mesh products include:

- Nickel

- Monel (nickel, alloy)

- Plastic

- Teflon

- Brass

- Phosphor Bronze

- Silver

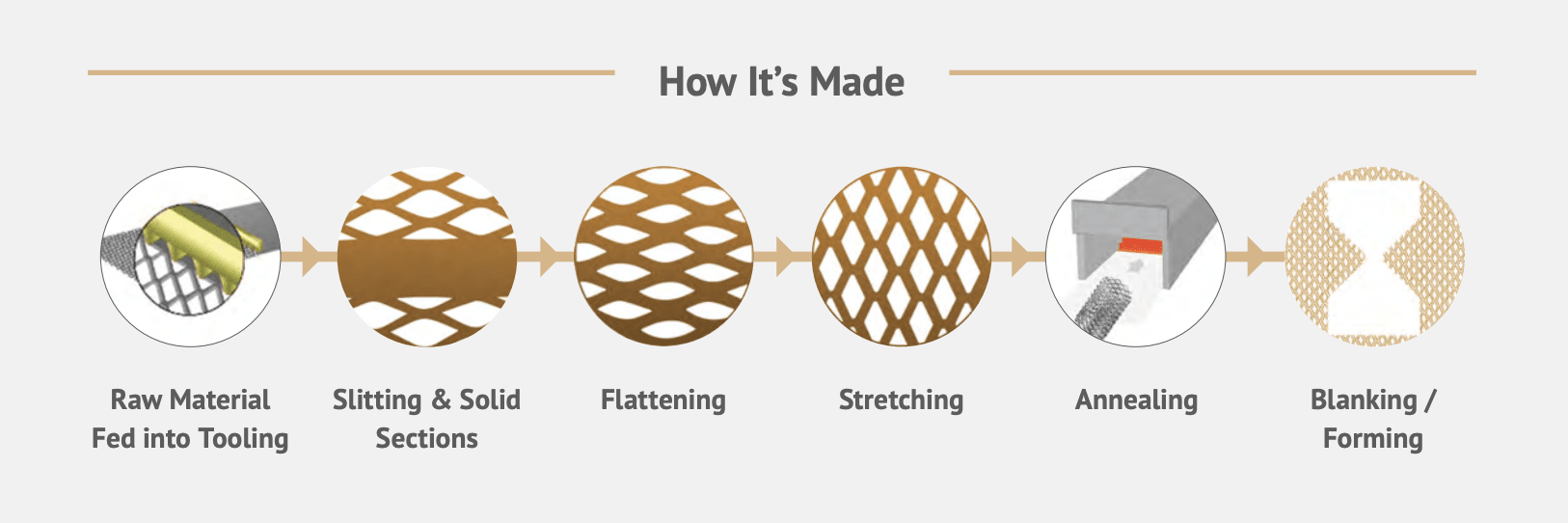

How Is Expanded Metal Foil Made?

Manufacturers follow these steps to manufacture expanded metal foils:

- Step one. The manufacturer inserts the raw material sheet into the expanded metal machinery.

- Step two. Once the raw material is in the machinery, it is slit and stretched based on the customer’s thickness and shape specifications. Depending on the intended use, this manufacturing process is compatible with a range of polymers and metals, including copper, aluminum, nickel and titanium.

- Step three. To facilitate easy delivery and application, the material is re-wound into a roll after it exits the machine.

Expanded Metal Foil: Our Process

We use precision proprietary expanding technology to cut metal foils into various thicknesses, shapes, and configurations. Your application’s requirements determine the expanded metal’s material, overall thickness and configurations.

CThru offers standard diamond sizes from 0.030”- 0.500”, with the number of openings per square inch varying from 25 to 5,000.

Learn more about how expanded metal foil is manufactured

Applications Using Expanded Metal Foil

CThru Metals offers a full suite of manufacturing capabilities to ensure we deliver the highest precision on your expanded metal project’s requirements.

CThru Mesh® is used in lightning strike protection for aircraft, wind turbine blades and other carbon fiber uses, batteries, electrodes, fuel cells, heating elements, filtration and a host of other applications. We work with a variety of materials, including copper, aluminum, titanium, stainless steel, exotic alloys and plastics. We meet exact specifications for thickness, strength, weight, open area and resistivity.

Expanded metal foil can be used for a wide variety of applications across diverse industries. Some of the most common applications for CThru Metal’s expanded metal foil include:

Lightning Strike Protection

Lightning Strike Protection

For applications such as wind turbines and airplanes, manufacturers often embed expanded metal mesh into various structures and composite surfaces to safely dissipate electrical energy after a lightning strike. By providing a conductive path, expanded metal foil protects composites from delamination, burns, and other damage caused by lightning.

Filtration Applications

Filtration Applications

Expanded metal materials are suitable for use as filter media or filter media support structures in various automotive and industrial applications. For example, expanded metal is often used as the main support structure in oil filtration, hydraulic, and airbag inflator systems.

EMI Shielding

EMI Shielding

Expanded metal foil can be used to shield against electromagnetic interference (EMI) in various electronics applications. Expanded metal offers an electrically continuous and homogeneous surface for effective and consistent EMI shielding in products ranging from gaskets to computers and more.

Renewable Energy Applications

Renewable Energy Applications

Due to its shielding capabilities and electrical properties, expanded metal foil is suitable for use in emerging renewable energy technologies. For example, it can be used for current collection or catalyst and membrane support in battery and fuel cell applications.

Expanded Metal Foil from CThru Metals

At CThru Metals, we are an industry leader in producing innovative and advanced expanded metal foil solutions for industries such as renewable energy, filtration, automotive, electronics, aerospace, and more. To ensure optimal cost-effectiveness and speed, our custom expanding equipment is designed to operate twice as fast compared to standard expanding machines.

If you have any questions about the configurations required for your application, please don’t hesitate to contact our team of experts.