Protect critical components and systems from electromagnetic interference with CThru MeshTM precision expanded metal foils

What is Electromagnetic Interference (EMI)?

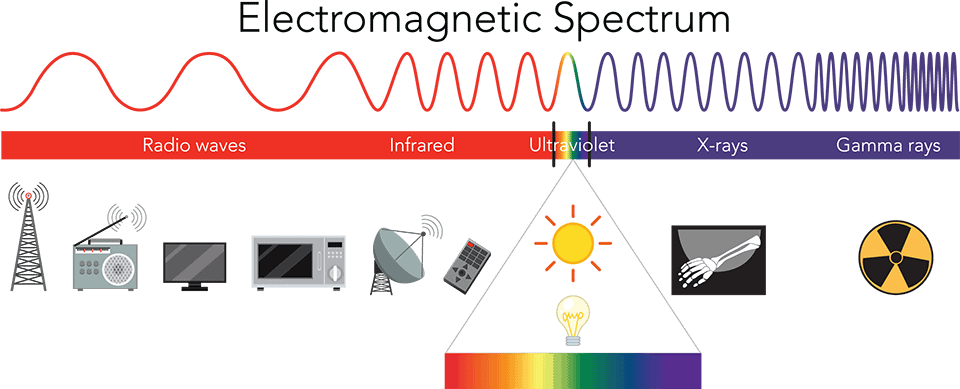

Electromagnetic Interference happens when a signal for an electronic device or system is interrupted by signals from other sources. This loss of signal impacts the intended performance of the device. EMI is generated from both electrical flow and magnetic fields. As electricity flows through a system it naturally generates a magnetic field. At the same time a moving magnetic field creates an electrical current. Many sources of EMI are all around us.

Sources of EMI

Sources of EMI are both natural and man-made. Solar flares from the sun release huge eruptions of electromagnetic ionizing radiation containing both x-rays and gamma rays. This energy travels at the speed of light, lasting from seconds to hours. NASA predicts this naturally occurring interference to continue to increase through 2025. Additionally, lightning strikes generate large concentrated bursts of EMI when they occur. Our everyday life generates and introduces EMI into the world. Things like radio and TV signals, electric motors, microwaves, fluorescent lighting, electrical transmission lines, cell phone signals, and wifi networks all create EMI. EMI has also become a weapon. Intentional Electromagnetic Interference (IEMI) has made its way into military playbooks to confuse and eliminate threats and leveraged by terrorist organizations to threaten powergrids and water systems. As more sources of EMI are introduced into our world every day, factoring EMI shielding into the design of electrical systems has become increasingly important.

Impact of EMI

Signal interruption due to EMI causes negative impact to typical performance characteristics of the affected device. When systems like cell phones or wifi are affected by EMI it can cause annoyance and frustration manifesting itself in a dropped call or slow internet speeds. When systems for vehicle control, navigation, drones, mass transit, medical devices, energy, aerospace, military, defense, and Government experience EMI the impact of temporary disturbances range from the loss of critical data to potential mass casualties. EMI Shielding is a mandatory part of quality electrical system design.

EMI Shielding with CThru MeshTM Precision Expanded Metal Foils

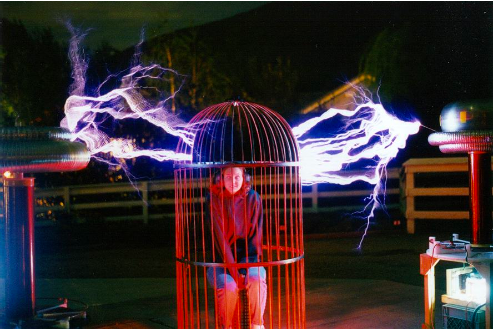

Much like the way a Faraday Cage creates a protective layer between an electrical field and the items inside it by providing a medium to redistribute the electrical field, EMI Shielding protects electrical components and systems from picking up the wrong signal, allowing the device to function as intended.

CThru MeshTM precision expanded metal foils prevent electromagnetic interference by surrounding your important electronics, absorbing any signal interference, creating a current across its surface from that rogue signal, and providing a path for the current to flow toivienne a ground connection – maintaining the intended functionality of your device and keeping the signal clean. CThru MeshTM precision expanded metal foils provide a continuous electrical path for consistent conductivity across the material enabling it to better absorb interference and dissipate the current created. Our material is pliable by design so it can conform to any contour or surface as needed to make an easy addition to complex manufacturing processes for EMI shielding of all aerospace/military systems, cables, carbon fiber products, electrical systems, enclosures, gaskets, and more.

The Shielding Effectiveness (SE) of CThru MeshTM is determined by the material selection, thickness of the foil, opening dimensions (SWO x LWO), and the number of openings. Our engineering team will work with you to create the custom configuration for weight, resistivity and EMI shielding effectiveness that will work for your application. All material performance validated and reported per ASTM D4935-10 at your request. The CThru MeshTM manufacturing process is faster than the competition and uses no lubrication. This means you get your material faster and ready to use without secondary cleaning, all at a project friendly price point. Request a sample of CThru MeshTM precision expanded metal foils to test in your application today.