Expanded metal mesh foil offers superior conductivity or resistivity while providing strength and light weight. It has many advantages compared to perforated metal and wire/woven mesh, and its use is beneficial in varying applications.

The main differences between each product type are the manufacturing process, the intended end-use, and the characteristics of the material. Expanded metal foil has unique properties that outperform other perforated and woven wire metals, such as:

- Enhanced Stability

- Increased Strength

- Excellent Conductivity

- Reduced Waste Generation

Expanded mesh is the preferred material choice in many industries due to the material’s ability to allow air, light, and fluid to pass through. The uniform diamond pattern creates structural integrity during fabrication, mitigating the risk of unraveling during manufacturing, which is often the case with woven mesh products.

The many advantages of expanded metal foil make it an ideal material choice that is lightweight, durable, and cost-effective.

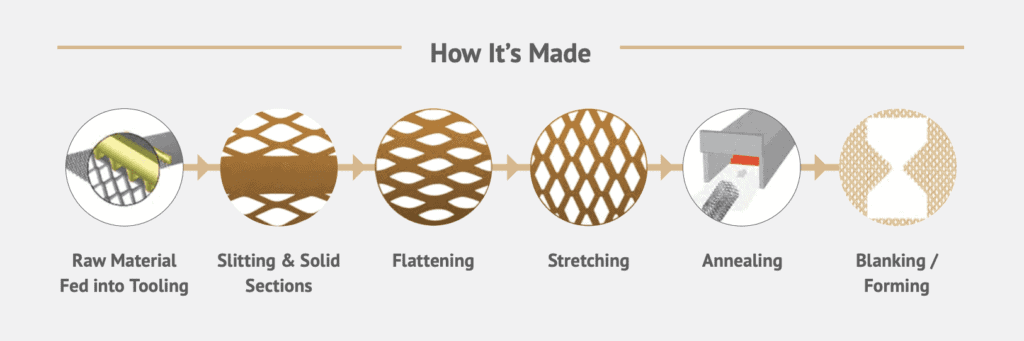

Expanded Metal Mesh – How It's Made

Expanded metals manufacturing follows this three-step process:

- An operator feeds the raw material into the metal expanding machinery.

- The machinery slits and stretches the material to the desired shape and thickness specifications, per the customer’s requirements. The manufacturing process is compatible with a broad range of metals and polymers, including titanium, nickel, silver, aluminum, and copper, depending upon the intended use.

- After exiting the machinery, the material is rewound to ensure simple delivery and application.

CThru Metals can cut metal foils to varying shapes and thicknesses using precision proprietary expanding technology. The customer’s requirements determine the expanded metal’s overall configuration.

Materials

The manufacturing of expanded metal mesh is compatible with a broad range of polymers and metals, each with unique properties suitable for varying environments and applications. Products produced from sheet metal include:

- Copper expanded mesh

- Titanium expanded mesh

- Aluminum expanded mesh

- Steel and stainless-steel expanded mesh

Some of the other materials we use to manufacture expanded metal mesh products include:

- Nickel

- Monel (nickel, alloy)

- Plastic

- Teflon

- Brass

- Phosphor Bronze

- Silver

Where Is Expanded Metal Mesh Used?

Expanded metal foil is an ideal solution for almost any industry that requires high-strength mesh materials. The versatile material is sufficiently resilient, durable, and conductive to support various systems and products.

Some examples of common applications include:

Lightning Strike Protection

Expanded metal mesh foil is a valuable resource for the wind turbine and aerospace industries. The material provides superior lightning strike protection when embedded into composite structures and surfaces, such as wind turbines and aircraft. After a lightning strike, the lightweight material dissipates the electrical energy without adding significant extra weight to the existing structure. It provides a conductive path that protects the composite from lightning-induced damage such as delamination or burns.

The single unit material does not unravel or fray and offers consistent conductivity over large surface areas. With hundreds of configurations to choose from, the expanded metal mesh can withstand a Zone 1 Strike of 200,000 amps.

EMI Shielding

When used in electronics applications, expanded metal creates a shield against electromagnetic interference (EMI). The material’s uniform, electrically continuous surface provides consistent EMI shielding in computers, gaskets, and other electronic components.

Unlike woven or knit meshes, expanded metal foils offer effective shielding and predictable conductivity over a broad range of frequencies. Common applications include:

- Shielded Enclosure

- Laminated Structures

- Gaskets

- Cable Shielding

- Ventilation Screens

Renewable Energy

New technology advancements in the renewable energy sector implement the use of expanded metal for its unique properties and shielding capabilities. In fuel cell and battery applications, expanded metals are utilized in everything from catalyst support to flow distribution.

Filtration

The automotive industry utilizes expanded metal as a primary support structure in oil filtration, airbag inflators, and hydraulic systems. Effective in various industrial applications, expanded metal materials are durable enough to provide filter media and media support.

CThru Metals can work with your specific application requirements to select a metal or polymer with geometries that offer primary filtration or work as media support for fine particle filtration cartridges. Choosing the proper material increases the filter lifespan while maximizing efficiency and reducing internal corrosion.

Choose CThru Metals For Your Expanded Metal Mesh Needs

We have extensive capabilities to manufacture custom expanded metal mesh foil in varying thicknesses, shapes, and configurations to meet your specific application requirements.

As an industry leader in innovative expanded metal foil solutions, we offer competitive pricing and faster lead times utilizing custom expanded metal manufacturing equipment capable of operating twice as fast as standardized equipment.

Our free white paper describes the expanded metal mesh process further. Download a free copy here and learn more about our custom expanded metal mesh capabilities.