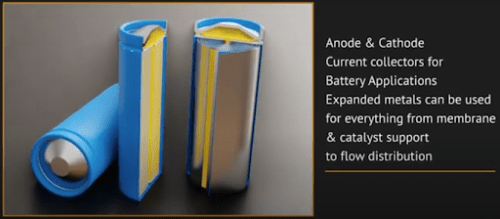

Increase capacity with anode and cathode battery electrodes made from CThru MeshTM expanded metal foils.

Anode and Cathode Battery Electrodes

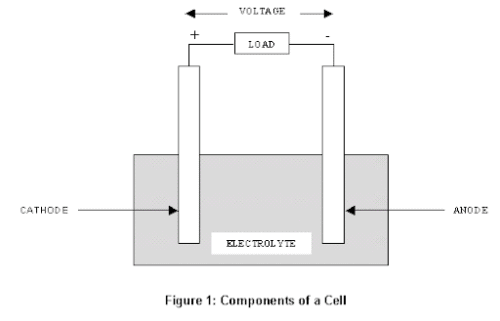

The three essential components of a battery that allow power to flow through the system are the Anode, Cathode, and Electrolyte. The anode is the negative electrode releasing electrons across the system. The cathode is the positive electrode collecting those electrons as they pass through the electrolyte. Most modern-day batteries utilize powder as the electrolyte due to its stability and high conductivity.

Traditional batteries use solid materials for the cathode and anode electrodes. New technologies and hand-held devices are straining the capacity and lifespan capabilities of batteries using this traditional design. How can we deliver a greater energy density and increased capacity while maintaining the standardized battery sizes used in so many devices?

CThru MeshTM Expanded Metal Foils Electrodes Improve Battery Capacity

CThru MeshTM expanded metal foil material is used as the anode and cathode electrodes in advanced Lithium-Ion batteries to increase energy density and overall capacity, primarily for aerospace, military, and defense applications. The perforated material provides a much greater surface area in comparison to traditional solid foil allowing for improved conductivity through the electrolyte. Most battery designs leverage CThru MeshTM as the supporting infrastructure holding the powdered electrolyte in place while acting as the positive and negative connections.

International battery manufacturers depend on CThru MeshTM expanded metal foil in their batteries to provide longer-lasting power for both primary batteries and secondary batteries.

CThru MeshTM Expanded Metal Foils for Battery Electrodes

The CThru MeshTM expanded metal foil material depends on the design requirements for conductivity and resistivity of your battery. We offer a wide array of materials to fit your most complex designs. We can supply the anode and cathode electrode materials for every design, from standard sizes to custom modular systems. All configurations are produced using the lubricant-free proprietary CThru Metals expanding process. This system is faster than our competitors which means you get your anode and cathode battery electrodes faster with no additional preparation requirements and a lower per part cost. Learn more about how CThru MeshTM expanded metal foil is manufactured or schedule a meeting with our DFM engineering team to get started on your project.