Selecting the right expanded metal for your project depends on the application’s requirements for strength, durability, appearance, conductivity, and a range of other factors. Because expanded metal is so versatile, we’ve put together this guide to assist engineers on how to choose the ideal expanded metal material based on their specific applications and goals.

Table of Contents

- What is Expanded Metal?

- Comparing Expanded Metal to Other Materials

- Types of Expanded Metal

- Key Selection Factors for Engineers & Manufacturers

- How to Source the Right Expanded Metal

- CThru Metals: Your Trusted Manufacturer of Lightweight Expanded Metal Mesh & Foil

What is Expanded Metal?

Expanded metal is created by slitting and stretching solid sheets of metal into mesh patterns. This process forms a strong structure with uniform openings. Unlike perforated metal, expanded metal does not punch holes through the sheet metal, which produces more waste material. And unlike woven wire mesh, which is made by interlacing individual wires, expanded metal does not unravel and thus offers greater structural integrity.

Comparing Expanded Metal to Other Similar Materials

Expanded metal is often compared to perforated metal and wire mesh:

- Expanded Metal vs. Perforated Metal: Expanded metal has higher strength, less scrap waste, better cost efficiency, and typically greater open area.

- Expanded Metal vs. Woven Wire Mesh: Expanded metal provides structural integrity without fraying, making it ideal for industrial and precise applications.

Engineers should choose standard expanded metal for heavier duty/structural applications, and expanded metal mesh for projects requiring lightweight and durable solutions as well as current collectors.

Benefits of expanded metal over perforated and woven wire include:

- Exceptional strength-to-weight ratio

- Enhanced airflow and visibility

- Cost-effective manufacturing process

Expanded metal materials will depend on the end use, but commonly include copper, aluminum, stainless steel, titanium, nickel, and brass, each offering unique properties such as corrosion resistance or conductivity. Leaders in the space like CThru Metals can also implement specialty materials like monel, phosphor bronze, and silver.

Types of Expanded Metal

Understanding different types of expanded metal ensures the best selection for your project:

- Typical thickness: ½” to 1½”

- Typical applications: Metal grates, security fencing, racks or shelving, strainers, speaker grilles, equipment enclosures.

Flattened Expanded Metal: Standard expanded metal can be flattened to provide a smooth, level surface suited and is typically lighter and more agile than standard expanded metal.

- Typical thickness: ¼” to 1½”

- Typical applications: Fencing, machine guarding, equipment enclosures, security partitions.

Expanded Metal Mesh: Unlike its thicker counterparts, expanded metal mesh requires higher levels of precision and smaller openings for its common end uses. Versatile and extremely lightweight, expanded metal mesh is thinner and flexible with precise openings. It is the material of choice for lightning strike protection, battery electrodes, EMI shielding, filtration, and other precision applications.

- Typical thickness: As thin as 0.001” (25 microns)

- Typical applications: Lightning strike protection in aircraft or wind turbines, EMI/RFI shielding, battery electrode materials, industrial filtration.

Key Selection Factors for Engineers and Manufacturers

When selecting the right type of expanded metal for their project, engineers and manufacturers should consider the following specifications:

How to Source the Right Expanded Metal

First, consider your application needs and desired thickness. Applications like lightning strike protection, EMI/RFI shielding, battery electrodes, fuel cells, or any application where weight is a factor will require ultra-lightweight design and a manufacturer who specifies in precision expanded mesh.

It’s also ideal for engineers to select a vendor who not only offers customization in mesh size, materials, and coatings, but who can be a true partner and assist you with selecting the right specifications and manufacturing processes to ensure optimal performance.

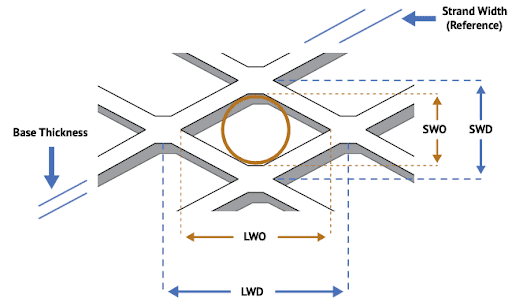

For example, selecting the right diamond size and number of openings per square inch will impact the performance of its application. Whether your application’s end use requires corrosion resistance, the ability to disperse electrical currents, or to screen or filter materials, the right expanded metal mesh partner will ask questions to determine the right material based on these requirements and ensure superior performance in its environment.

An industry expert like CThru Metals will guide you through this process during the quoting stage.

>> Need a Quote? Make Sure You Have the Right Specs—Read Our Quote Guide

CThru Metals: Your Trusted Manufacturer of Lightweight Expanded Metal Mesh & Foil

CThru Metals manufactures lightweight expanded metal mesh in standard diamond sizes from 0.030”- 0.500”, with the number of openings per square inch varying from 25 to 5,000. We can also manufacture your custom expanded metal configuration based on pattern, thickness, width, material, and blanking/forming the design.

Our proprietary expanding process runs faster than our competitors, with CNC-controlled smart technology that manufactures the mesh with greater consistency. As a result, our customers enjoy superior quality and faster delivery at a competitive cost.

- Customization & Versatility:

- Custom tailored thicknesses, strand widths, and mesh sizes.

- Advanced proprietary expanding technology for precision.

- Wide Material Range:

- Aluminum, copper, stainless steel options.

- Solutions for corrosion resistance, conductivity, filtration, and more.

- Quality You Can Trust:

- Lightweight yet superior performance compared to traditional materials.

- CNC-controlled expanding machinery ensuring consistent quality without defects.

- Stronger material that lasts and won’t fray or break.

- Lower Cost:

- Because CThru Metals uses less materials, our customers see savings as high as 50% when compared to competing materials like woven wire mesh.

- Fast Lead Times & On-Time Delivery:

- Domestic manufacturing capabilities for US clients ensure rapid turnaround.

- UK-based distribution center for efficient service in Europe.

Have Questions? Contact CThru Metals for Expert Support

Selecting the right expanded metal significantly impacts your project’s success. At CThru Metals, our mission is to deliver the highest quality, ultra-lightweight expanded metal at a cost to meet every budget. After working in the stamped metals industry for over 35 years, we realized we could provide a much-needed solution to our customers with superior expanded metal at a level of quality that no other competitor could deliver.

Leveraging our engineering expertise, we built our own proprietary equipment to innovate a century-old industry with 21st-century smart technology. The result: lighter, stronger, and better performing material.

Let’s talk through what your project needs today. Contact CThru Metals for expert assistance in choosing the best materials for your engineering needs.