CThru Metals is a leading expanded metal mesh manufacturer specializing in ultra-fine micro expanded metal mesh solutions. We produce precision-engineered mesh (also known as fine expanded metal mesh or micro-mesh material) that is lightweight, durable, and extremely conductive, with a high open-area percentage for optimal airflow and transparency.

Our custom expanded metal products—sometimes called fine mesh metals or micro metal foils—offer the strength of solid sheet metal at a fraction of the weight, making them ideal for demanding applications. We proudly serve key industries including aerospace, energy storage, electronics, and industrial filtration, delivering fine stainless steel mesh and other custom expanded metal foils tailored to each sector’s needs.

Speak with a Expanded Metal Specialist

CThru Metals’ Premium Expanded Metal Mesh Solutions

Our team provides premium expanded metal mesh solutions via CThru Mesh™ expanded metal foil, and our advanced manufacturing capabilities set us apart from other expanded metal manufacturers.

Discover CThru Mesh™: Precision-Engineered Expanded Metal Foil

Discover CThru Mesh™: Precision-Engineered Expanded Metal Foil

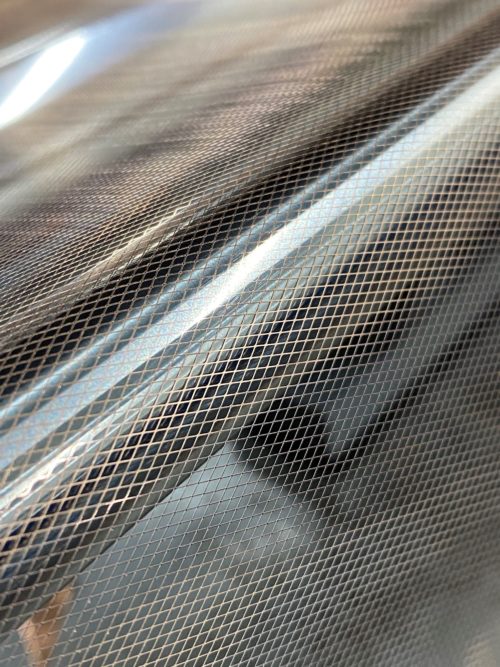

CThru Mesh™ is our signature ultra-fine expanded metal foil, engineered for maximum performance. This precision product is manufactured from a single piece of metal that is expertly slit and stretched into a uniform mesh pattern. Unlike woven wire cloth, expandedmetal foil’s one-piece structure eliminates the potential for unraveling while maintaining exceptional strength. In addition, our CNC-controlled expanding machines continuously test the material during production to ensure superior consistency throughout the entire material.

Configurations & Specifications

CThru Metals offer a wide range of mesh configurations, with diamond opening sizes from approximately 0.030” up to 0.500”. Mesh density can vary from about 25 up to 5,000 openings per square inch, allowing us to create everything from coarser grids to incredibly fine micro mesh. We also accommodate various material thicknesses from ultra-thin 0.001” foils (25 microns) up to around 0.016”, giving you a broad spectrum of micro metal material options to meet your design requirements. (Learn more on our detailed Expanded Metal Foil page.)

Material Selection

Our micro expanded metal mesh is available in an extensive selection of materials. CThru Metals regularly produces fine mesh in copper, nickel, aluminum, titanium, and stainless steel, including specialty alloys. If you need a fine stainless steel mesh for corrosion resistance, or an ultra-light aluminum micro mesh material for weight savings in aircraft or other applications, we can deliver the right solution. Each expanded mesh can be further customized with different strand widths, pattern orientations, and open-area percentages to achieve the exact performance characteristics you need.

CThru Mesh™ foil outperforms traditional metal meshes like woven wire or perforated sheet in several ways:

- First, our expanded mesh has higher electrical conductivity and more uniform coverage, making it perfect for applications that require efficient current transfer or EMI shielding.

- Second, the continuous pattern provides excellent structural integrity and load distribution, yielding greater strength and durability for its weight (no weak welds or joints).

- Additionally, expanded metal generates far less waste during manufacturing than perforated metal, since there are no scraps punched out—this cost-efficiency allows us to offer competitive pricing.

- Compared to typical woven wire mesh, our expanded metal is also more consistent (thanks to CNC-controlled expansion) and won’t develop contact resistance or loose threads.

In short, CThru’s fine expanded metal mesh provides a lightweight expanded metal solution with superior performance and reliability for high-tech industries.

Custom Micro Mesh

Customization is a cornerstone of CThru Metals’ approach. We use proprietary, CNC-driven expanding machines (lubricant-free and precision-controlled) to create new mesh patterns in-house for unique applications.

Our engineers can tailor every aspect of the mesh—from strand width and diamond shape to material and temper—to meet exacting specifications. Whether you need an entirely new micro-mesh pattern or adjustments to open area, thickness, or roll width, we have the capability to design and manufacture a truly custom expanded metal product.

This flexibility, combined with our precision processes, means you get exactly the mesh you envision for your project, rather than a one-size-fits-all catalog item.

Custom Expanded Metal Mesh Manufacturing Capabilities

Custom Expanded Metal Mesh Manufacturing Capabilities

To deliver the highest quality expanded metal mesh, CThru Metals employs a full suite of advanced manufacturing capabilities. Our production facility is equipped to not only expand metal, but also to refine and finish it to your requirements. We offer:

- Flattening: Reduces mesh thickness and creates a smooth, flat surface (ideal when a low-profile, fine mesh is needed).

- Stretching: Adjusts the mesh’s open dimensions by further elongating the pattern, useful for achieving greater pocket depth or open area in applications like battery electrodes and filtration.

- Annealing: In-house heat treatment to relieve stress and normalize the micro mesh material after expansion, ensuring the expanded metal foil retains ductility and meets exact mechanical specs.

- Custom Blanking: Precision stamping of expanded sheets into specific shapes or profiles. We can blank parts with tolerances as tight as ±0.001”, enabling complex geometries for your custom expanded metal components.

- Slitting: Accurate slitting of coils to narrower widths (down to ~0.5 inches) with multiple cuts at once. This allows us to deliver expanded metal rolls or strips that fit your assembly without additional machining.

- Automated Cutting (Cut-to-Length/Shape): Computer-controlled cutting equipment for trimming mesh to exact lengths or custom shapes, improving efficiency and consistency across high-volume orders.

- Engineered Packaging: Customized packaging solutions (including protective wrapping and special spool designs) to prevent any damage to the fine mesh during handling and shipment. Your rolled micro mesh material will arrive in perfect condition and is easy to deploy on your production line.

These comprehensive capabilities (and more—see our Manufacturing Capabilities page) ensure that we can deliver expanded metal meshes to precise specifications, ready for immediate use in your manufacturing process. From initial expansion through finishing and packaging, every step is carefully controlled for quality and consistency.

Industrial Applications

Expanded metal mesh is an incredibly versatile material, used in dozens of industries that require a combination of low weight, conductivity, and structural support. CThru’s lightweight expanded metal mesh and foil products find application in a wide range of industrial and high-tech sectors. Here are just a few examples of where our fine mesh metals are making an impact:

- Aerospace & Wind Energy (Lightning Strike Protection): Ultra-fine expanded metal foils (like CThru Mesh™) are embedded into composite aircraft structures and wind turbine blades to safely dissipate lightning strikes. The micro expanded metal layer provides a conductive path across the surface, protecting carbon fiber components from delamination or burn-through without adding significant weight.

- Energy Storage (Batteries & Fuel Cells): Micro expanded metal mesh serves as an excellent current collector and electrode support in batteries and fuel cells. Materials like fine copper or nickel mesh offer high conductivity and large surface area, improving battery performance and enabling lightweight, compact energy storage devices. The mesh’s open structure also facilitates uniform distribution of electrolytes and gases in advanced battery and fuel cell designs.

- Electronics (EMI/RFI Shielding): Expanded metal mesh is used to create reliable EMI/RFI shielding in electronics and telecommunications. A fine stainless steel mesh or copper mesh can form an electrically continuous enclosure or gasket that blocks electromagnetic interference. Because expanded mesh has no breaks or weak links, it provides consistent shielding effectiveness across enclosures, cables, and components in sensitive devices.

- Industrial & Automotive Filtration: Many filtration applications rely on fine expanded metal mesh as either the filter medium or a support for filter elements. For example, stainless expanded metal is used in oil and hydraulic filters, offering a durable mesh that resists corrosion while trapping contaminants. In automotive safety systems, micro expanded metal screens serve as igniter filters (airbag inflator filters) and in fuel strainers, with precisely controlled pore sizes to ensure proper flow and filtration efficiency.

These are just a few featured applications. In practice, CThru Metals’ expanded mesh can also be used in medical devices, heating elements, and any scenario where a strong yet open-area metal material is required. Our engineers can advise on the best mesh configuration for your specific industry application, leveraging our experience across aerospace, renewable energy, electronics, filtration and more.

Why Choose CThru Metals for Micro Expanded Metal Mesh?

When it comes to ultra-fine expanded metal, CThru Metals offers a combination of technology and expertise that is hard to match. We understand you have options among expanded metal mesh manufacturers, but our unique strengths make us the premier choice for micro mesh projects. Here’s what sets CThru apart:

- Custom Capabilities & Expertise: We thrive on customization. CThru Metals has decades of metal forming experience (over 30 years in the industry) and a skilled engineering team ready to develop custom expanded metal solutions. Whether you need a brand-new mesh pattern or a specialty alloy, we have the know-how to design and produce it. Our deep industry expertise in aerospace, energy, and filtration means we can collaborate on specifications and recommend the optimal fine mesh metals for your use case.

- Unmatched Precision with Advanced Equipment: Quality and precision are built into our process. We are the first in our field to introduce CNC-controlled expanding machines, enabling extremely consistent mesh production at micro scales. Our proprietary expanding equipment is self-adjusting and lubricant-free, ensuring each ultra-thin foil comes out clean and accurate to your specs (no oil residue or warped strands). We routinely achieve tighter tolerances and thinner gauges than any other expanded metal manufacturers—delivering a product that meets the most exacting standards for thickness, open area, and electrical conductivity.

- Superior Quality & Certifications: At CThru, quality assurance is paramount. We maintain rigorous QA/QC processes and are certified to ISO 9001:2015 for our quality management system. In September 2024, we also achieved AS9100D certification, reflecting our commitment to the highest aerospace industry standards. Every micro expanded metal mesh we ship undergoes thorough inspection to ensure it matches your specified thickness, strength, and resistivity. The result is a durable, high-performance mesh you can trust for mission-critical applications.

- Fast Turnaround & Customer-Centric Service: We pride ourselves on responsive service and cost-effective solutions. Our streamlined production and domestic manufacturing mean short lead times – you get your custom mesh quickly, avoiding project delays. We also offer a global reach with a UK-based distribution center for faster delivery to international customers. Furthermore, expanded metal’s efficient process (with minimal waste) allows us to provide competitive pricing without sacrificing quality. From first contact through delivery, our team focuses on your needs, offering technical support, quick quotes, and on-time performance to ensure your success.

In summary, CThru Metals combines superior precision, material quality, and customer-focused collaboration to deliver micro expanded metal mesh that stands above the rest. When you partner with us, you gain a trusted supplier dedicated to meeting your exact requirements and exceeding your expectations.

>> Need a Expanded Metal Mesh Project Quote? What You Need to Know

Ask About Our Lightweight Expanded Metal Mesh Foil

Ready to elevate your next project with lightweight, high-precision expanded metal mesh? We’re here to help. CThru Metals offers the ultra-fine micro mesh and personalized service you need to drive innovation—whether it’s improving aircraft safety, boosting battery performance, or developing a new filtration system. Our specialists are happy to discuss your project goals and recommend the ideal expanded metal solution. Experience the difference that precision-engineered, custom expanded metal foil can make in terms of strength, conductivity, and weight savings. Contact us today to speak with an expert about your application, or request a quote to see the CThru Metals advantage firsthand.

We look forward to providing you with the finest expanded metal mesh on the market and becoming your long-term manufacturing partner.

Discover CThru Mesh™: Precision-Engineered Expanded Metal Foil

Discover CThru Mesh™: Precision-Engineered Expanded Metal Foil Custom Expanded Metal Mesh Manufacturing Capabilities

Custom Expanded Metal Mesh Manufacturing Capabilities