When working with a custom expanded metal mesh supplier, the company you choose should work closely with you to develop a custom product that suits your exact requirements and specifications. This checklist will guide you through the primary information to provide your supplier during the quoting process to ensure they can meet your needs and provide high-quality expanded metal mesh within your timeline.

What to Have Ready for Your Supplier

Before you request a quote from a prospective supplier, have a list of your project needs ready. You should provide information such as:

- Type of Raw Material Alloy. There are various raw material alloys available, each offering its own unique properties and benefits. It is crucial to consider your application’s requirements for cost, corrosion resistance, density, hardness, yield strength, tensile strength, elongation, magnetism, bend rating, and more when choosing the right expanded metal material.

- Raw Material Thickness. Years ago, metal foil could be expanded as thin as 50 microns and up to 36 inches in width. Today, metals can be expanded down to 30 microns and 40+ inches in width, with more advanced technologies capable of expanding metals even wider.

- Coil Width. Creating expanded metal foil involves slitting and stretching a lightweight metal coil to produce a consistent mesh pattern of openings.

- Raw Expand Length. Expanded metal is an ideal solution for applications where weight is crucial due to its ability to be produced thinner than alternative open area materials. Long coil lengths are only limited by raw material availability and finished coil weights.

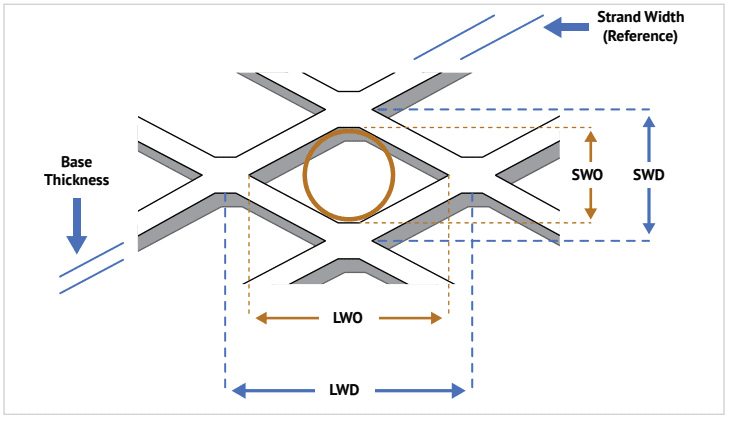

- Strand. Key measurements of expanded metal mesh include strand width (SW), short way of the diamond (SWD), and long way of the diamond (LWD).

- SW. This refers to the amount of material that should be slit from the parent material to form the opening.

- SWD. This refers to the distance from one joint’s center to the adjacent joint’s center across the diamond’s short axis.

- LWD. This refers to the distance from one joint’s center to the adjacent joint’s center across the diamond’s long axis.

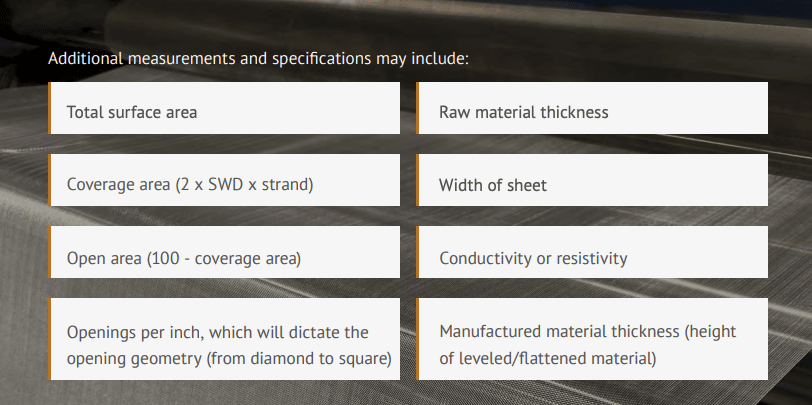

- Leveling. If your project is working with leveled materials, you must provide the thickness of the leveled/flattened material (manufactured material thickness).

Get Your Expanded Metal Mesh Project Quote From CThru Metals

Before you request a quote from a supplier for your expanded metal mesh project, you must gather the necessary information regarding certain measurements and specifications for your project. Everything from the type of alloy required to specific dimensions and more must be provided to ensure the most accurate quoting process.

At CThru Metals, our extensive capabilities in expanded metal manufacturing allow us to produce custom metal mesh in a wide range of shapes, thicknesses, and configurations to meet your specific needs. Our standard diamond sizes range from 0.030’’ to 0.500’’ LWD, with the number of openings ranging between 25 to 5,000 per square inch. As an industry leader in advanced and innovative expanded metal foil solutions, we offer faster lead times and competitive prices using custom expanded metal manufacturing equipment that operates two times faster than standard metal expanding equipment.

For more information about our custom expanded metal mesh capabilities, or to work with us on your next project, request a quote today.

Tags: expanded metal mesh