Expanded Metal Mesh Specifications

Expanded metal mesh is a coil of thin metal that has been precisely slit and stretched to form a uniform, mesh-like material with a regular pattern of openings (often diamond-shaped). Unlike woven wire mesh, expanded metal is made from a single piece of metal that is never completely cut—this creates a one-piece mesh with no welded joints, resulting in excellent conductivity and structural integrity.

The example above shows a fine micro-expanded metal foil with miniature diamond-shaped openings.

CThru Metals specializes in micro expanded metal products, sometimes called expanded metal foil, which are made from very thin gauges of metal to create extremely fine meshes. The expanded metal process produces a material that offers precision, valuable in applications like lightning strike protection, current collection, filtration and EMI shielding— with significant weight savings compared to solid sheet metal (since much of the sheet becomes open area).

Expanded metal’s combination of strength and low weight makes it ideal for aerospace, energy storage, and other high-performance industries. Specifications are critical when discussing expanded metal because they determine the mesh’s performance characteristics—everything from filtration efficiency and airflow to structural rigidity and weight per area depends on getting the specs right.

In this post, we’ll explore the key expanded metal mesh specifications—such as SWD, LWD, strand width, gauge, open area, and more—and explain how to choose the right spec for your application.

Key Expanded Metal Specifications & Definitions

When reviewing expanded metal mesh specifications, you’ll encounter a variety of technical terms and acronyms. Understanding these definitions is important for engineers to correctly specify the mesh and ensure it meets the application’s requirements. If you’ve ever wondered about SWD’s meaning or LWD’s meaning on a spec sheet, here we clarify those and other key expanded metal terms:

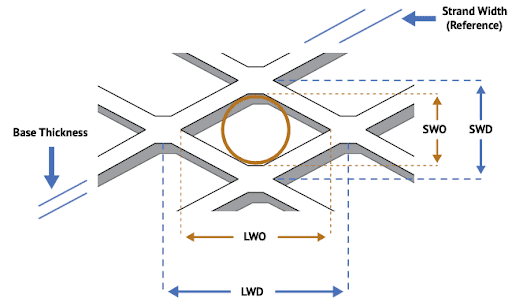

. LWD (Long Way of the Diamond)

LWD stands for “long way of the diamond,” referring to the length of the longer diagonal of each diamond opening. It is measured from the center of one node to the center of the next node along the long axis of the diamond. LWD is typically larger than SWD, since it’s the longer dimension of the diamond shape.

A larger LWD yields greater overall open area and can improve airflow or visibility through the mesh. But it can also make the mesh less flexible and more rigid along the long axis. Conversely, a smaller LWD (closer in size to the SWD) results in a more uniform, square-like opening and can enhance the mesh’s strength because the strands are closer together.

. SWD (Short Way of the Diamond)

SWD stands for “short way of the diamond.” This refers to the length of the shorter diagonal of each diamond-shaped opening, typically measured from the center of one node (intersection of strands) to the center of the adjacent node along the short axis of the diamond.

In simpler terms, it’s the short dimension of each opening including the material between nodes. A smaller SWD generally means a tighter mesh (more diamonds per area), which can increase the mesh’s flexibility in one direction and create a finer filtration screen. A larger SWD means the diamonds are elongated in the short direction, usually making the mesh slightly more rigid along that axis and reducing the number of openings per area. The SWD is critical for applications that need a certain mesh density or are concerned with how the mesh will flex or drape in the direction of the short diagonal.

Together, SWD and LWD define the basic geometry of the expanded mesh openings and are usually given in inches or millimeters. For example, an expanded metal spec might list SWD = 0.25″ and LWD = 0.50″ for a certain mesh pattern.

. SWO and LWO (Short Way of Opening, Long Way of Opening)

These terms refer to the clear opening size of the mesh. SWO is the short way of opening, meaning the distance between the inner edges of the strands along the short diagonal. LWO is the long way of opening, the distance between inner strand edges along the long diagonal.

In other words, SWO/LWO measure only the open gap, whereas SWD/LWD measure from center-to-center of nodes (including the material). For any given mesh, SWO is slightly smaller than SWD (by roughly one strand width), and LWO is smaller than LWD. These opening dimensions are very relevant for filtration and open area.

For example, if you’re designing a filter and need to block particles above a certain size, you would look at the SWO/LWO to know the actual free space a particle could pass through. Similarly, for applications like architectural screens or EMI shielding, SWO/LWO tell you how much light or electromagnetic waves can pass. Designers will specify SWO/LWO when the exact aperture size is critical to the function (whereas SWD/LWD are used for the overall mesh pitch including the strands).

. Strand Width (SW)

Strand width is the width of the metal strips that make up the sides of each diamond opening (the material between the openings). In the expansion process, strand width corresponds to how much metal remains after slitting and stretching. A wider strand width means each “ligament” of metal is broader. This has a direct effect on strength and open area: wider strands yield a stronger, more rigid mesh (since there’s more metal mass in the pattern) but they reduce the open area percentage (because thicker strands take up more space, leaving smaller gaps). Narrow strands increase the open area and improve airflow or transparency, but the mesh will be less robust and may be more prone to deformation.

Engineers will choose a strand width based on the needed balance between strength and open area. For example, a heavy load-bearing platform might use an expanded metal with thick, wide strands for maximum strength, whereas a fine filter or shielding mesh uses very thin strands to maximize open space. (Note: Strand width is different from strand thickness – width is the measurement in the plane of the coil, while thickness is the gauge of the metal.)

. Thickness (Gauge)

The thickness of expanded metal is essentially the thickness of the original sheet or coil before expansion, often expressed as a gauge or in millimeters or inches. This is sometimes called strand thickness. For standard (raised) expanded metal, the final thickness is approximately twice the strand width. In flattened expanded metal, the coil is run through flattening rolls after expansion to make it flat; this process compresses the strands a bit, so the finished thickness of a flattened mesh is usually close to the original metal thickness.

When specifying expanded metal, one should clarify if the thickness refers to original material thickness or final mesh thickness (especially for flattened mesh). CThru Metals specializes in ultra-thin expanded metal foil, which can be made from extremely thin gauges. Standard expanded metal products might use thicker gauges (e.g. 16 gauge, 0.062″ steel, or even heavier for grating). In contrast, micro expanded metal foil is made from foils just a few thousandths of an inch thick. Our advanced expanding technology can produce metal foils as thin as around 25–50 microns (0.025–0.05 mm) into mesh.

Thinner gauge expanded mesh yields a very lightweight product which is excellent for weight-sensitive applications like aerospace, but handling and supporting such thin mesh requires precision (it’s flexible and delicate compared to thicker meshes). Always note whether a thickness spec is “pre-expansion” (the raw material gauge) or “post-expansion” (for flattened mesh or final product) to avoid confusion.

. Open Area (%)

Open area is the percentage of the total sheet area that is open space (the holes) after the metal is expanded. It is calculated based on the strand width, strand thickness, and SWD/LWD of the pattern. For example, a pattern might be specified as having 70% open area, meaning 70% of the mesh is empty space and 30% is metal strands.

Open Area is a critical spec for many functional reasons: if you need maximum airflow or fluid flow through the mesh (like in ventilation panels or filters), a high open area percentage is desirable. High open area also correlates with better visibility through the mesh (important for applications like security screens or window guards where you want to see through the mesh). However, increasing open area (by using thinner/narrower strands or larger openings) will reduce the mesh’s strength. Engineers must strike the right balance—just enough open area to meet airflow or filtration targets, while still retaining sufficient metal for strength.

Expanded metal can be made with open areas from just a few percent (very heavy, secure meshes) up to over 90% (extremely fine, thin meshes used for things like EMI shielding or battery current collectors). Knowing the required open area helps in selecting the SWD, LWD, and strand dimensions that achieve that target.

. Material Weight (Weight per Area)

Expanded metal is often specified with a nominal weight per unit area, such as pounds per square foot (lbs/ft²) or grams per square meter (g/m²). Because expanded metal removes a lot of material to form openings, it provides a huge weight advantage. For standard expanded metal used in construction, weight might be given in lbs per 100 square feet, for instance.

For expanded metal foil (micro-mesh), it’s common to use grams per square meter since the material is so light. For example, an ultra-thin expanded aluminum mesh might weigh only ~30 g/m² (versus a solid aluminum sheet of the same thickness which would be many times heavier). Weight per area is a handy spec for engineers concerned with overall system weight or comparing materials. In aerospace and automotive design, specifying a lighter mesh (lower g/m²) can contribute to fuel efficiency and performance. Keep in mind that material type affects weight too (steel is heavier than aluminum for the same geometry; copper is heavier than aluminum but offers other benefits like conductivity).

When comparing expanded metal options, consider both the open area and the base material density to get the weight-per-area. CThru’s expanded metal foils are designed for lightweight design optimization — for instance, our thin expanded titanium or aluminum foils provide the necessary strength or conductivity at a fraction of the weight of a traditional expanded sheet.

In summary, these specifications (SWD, LWD, SWO, LWO, strand width, thickness, open area, and weight) define an expanded metal mesh’s geometry and performance. An engineer will use these parameters to ensure the mesh meets the precision requirements of the project. For example, specifying the correct SWO/LWO ensures your filter will catch particles of the right size; choosing the right strand width and gauge will make sure the mesh supports structural loads; and targeting the appropriate open area and weight will meet goals for airflow and weight savings.

Understanding this terminology will also help you communicate with suppliers and compare products accurately.

Choosing the Right Micro Expanded Mesh Specs for Your Application

With an understanding of the key specs, the next step is selecting the right expanded metal mesh specification for your specific application. Micro expanded metal (ultra-fine foil mesh) offers a lot of tunability to meet different design goals. Here is a simple guide for engineers on how to choose specs based on various project objectives: